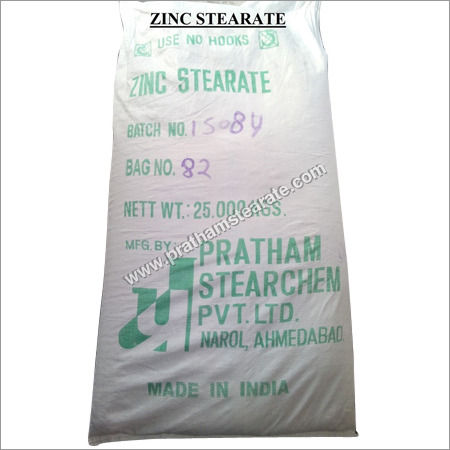

Offering a wide range of Chemicals that include Calcium Stearate, Sodium Stearate, Zinc Stearate, Magnesium Stearate, XLPE Repair Tape etc.

Offering a wide range of Chemicals that include Calcium Stearate, Sodium Stearate, Zinc Stearate, Magnesium Stearate, XLPE Repair Tape etc.

PRATHAM UDYOG Group was established in the year 1997. It was founded by Mr. R.K. Agarwal, who holds B.Tech Degree in Chemical Engineering (1978 Batch) from IIT Kanpur. Post-graduation, Mr. Agarwal worked with many reputed organizations. He started his career with Indian Aluminium Co. Ltd., which is a multinational company and also a subsidiary of Canadian Aluminium Company-ALCAN. He worked with this organization for 14 years. Then, he worked with Caprihans India Ltd as Works Manager and Jay Agrochem Ltd as a Chief Executive for around three years each.

In the year 1997, Mr. Agarwal founded Pratham Udyog and started manufacturing high quality Stearates of different metals. Since then, we have been supplying these chemicals along with other PVC Stabilizers like DBLP, TBLS, DBLS, etc. to several PVC Pipe manufacturers in the country. We not only supply our products to PVC Pipe industry, but also to the Paint Industry, Cable Industry, PVC/PP Compounding Industry, etc.

Applications

Our products are widely demanded for various applications in:

- Processing of polymers

- Textile Industry

- Cosmetic and Pharmaceutical industries

- Manufacturing of soft drinks and Ice cream products

- Cement paver blocks

- Construction chemicals.

Quality Assurance

Since

the inception of the organization, we have never compromised with the

quality of our Chemicals, as we believe quality is the most important

element for earning the trust of any client. We use Statistical Quality

Control Methodology as a management tool that enables us to maintain

strict control over the entire production process. We have also

appointed a team of quality controllers, who monitor the manufacturing

process, right from the procurement stage till the final stage of

delivery.

We have also established sophisticated QCD consisting of latest computerized instruments to carry out the quality testing activity with perfection and ease. For us quality is not just a word; It is a never-ending journey".

To ensure optimum reliability of the

formulations, we use high quality raw material in the production

process.

Manufacturing Unit

We boast of a modern manufacturing unit that is equipped with latest Boilers, Reactors, Filters, Dryers, Pulverizers and other equipment that allow us to formulate precise compositions for our valuable clients. These equipment combined with some of other processing machines are regularly updated by our expert team of technocrats and engineers, who leave no stone unturned to offer the best product range to our clients. They ensure maximum utilization of the available resources and offer the best products to our esteemed customers.

Our manufacturing process is completely environment friendly. We have arranged proper facilities to treat the waste material to avoid any harm to factory surroundings.